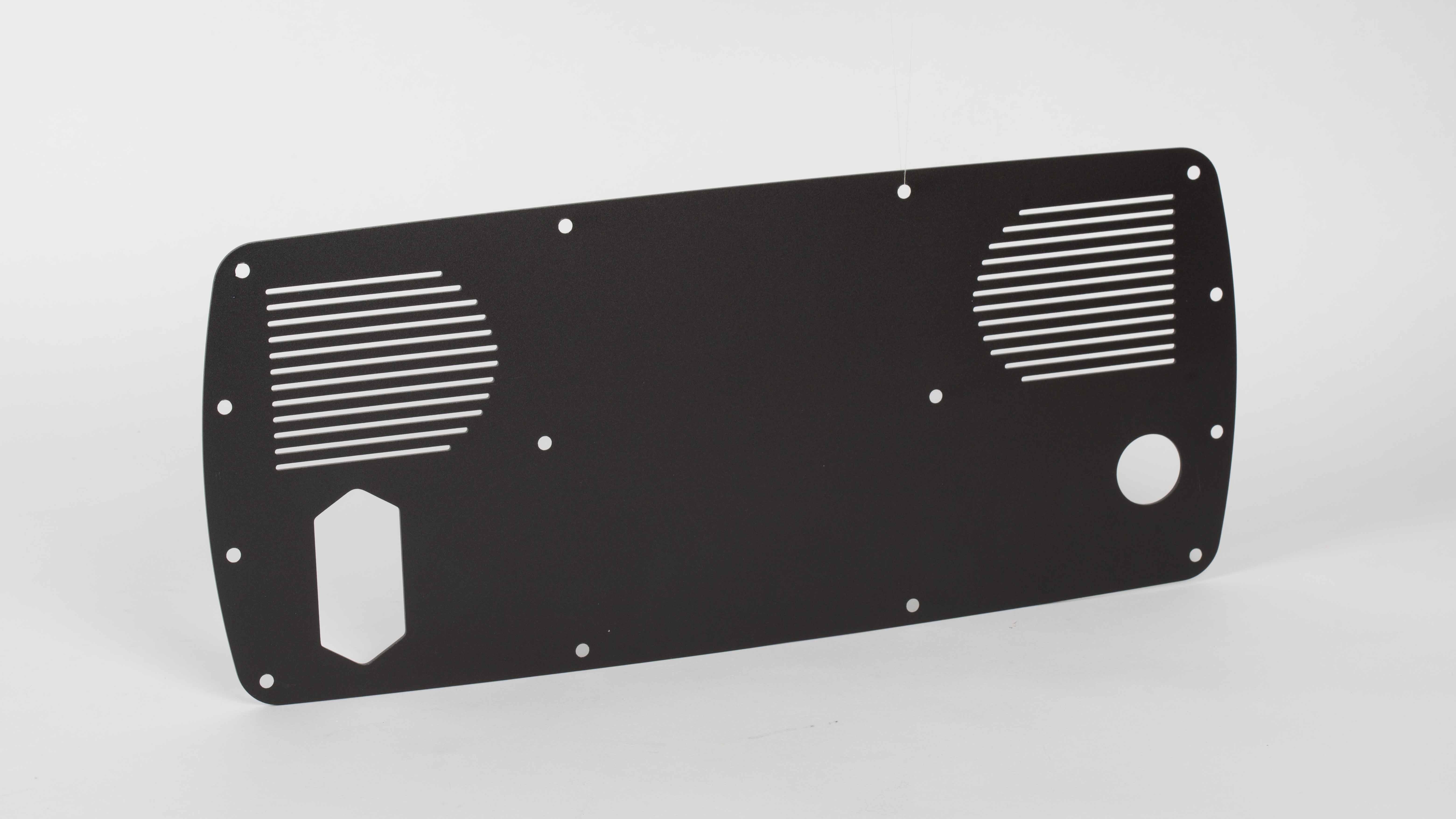

Prototype manufacturing in Mastars involves customers in various industries around the world. Products include medical equipment accessories, auto parts, motorcycle forged parts, 3C electronics, new energy, etc., including CNC processing, 3D printing, sheet metal, vacuum casting and other manufacturing processes

Processing technology of vacuum casting prototyping

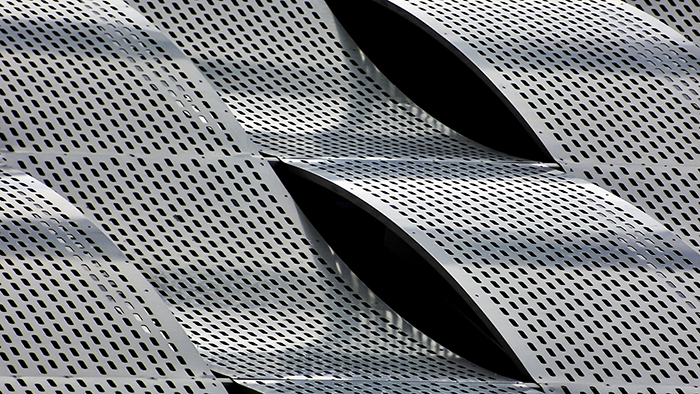

Vacuum casting prototyping is to use the original template to manufacture silica gel mold in vacuum, and pour with PU data in vacuum. If there are few samples to be manufactured, you can use the compound molding skills to manufacture. The manufacturing cost of compound mold is low, but the prototype template will shrink in a certain proportion. Compared with CNC, the price of vacuum casting manufacturing model will be lower. The Pu data of compound mold is divided into general Pu, Tongming Pu, rubber, etc. The specific process is as follows:

1. Original: before making silica gel mold, you need to make an original, which can be made by CNC processing or 3D printing.

2. Making silica gel mold: after the original is ready, start making silica gel mold. After eight hours of drying, cut the silica gel mold and take out the prototype. At this time, the silica gel mold is ready.

3. Injection: inject the liquid material into the silica gel mold and dry it. The service life of the silica gel mold is about 10 times.

Advantage of vacuum casting prototyping

1. The manufacturing cost is low, and the prototype manufacturing industry often uses vacuum silica gel mold for small batch replication production;

2. The service life of silica gel mold can reproduce and produce 10-20 same prototype products;

3. Fast speed, general working time: 1-4 hours / piece;

4. Standard copy accuracy of replica prototype: ± 0.20mm/100mm;

5. According to customer requirements, we can make products with exquisite appearance according to different colors;

6. It is suitable for trial production samples with complex product structure, uniform wall thickness and meeting certain functional requirements.

Disadvantage of vacuum casting prototyping

1. The original sample of the product is required before the re molding can be carried out. The original sample here can be provided by the customer or the prototype processed by CNC according to the customer's needs;

2. For products with large parts and thin product wall, whether there is shrinkage should be considered when making vacuum replica, resulting in small product size;

3. Prototype proofing cannot be produced in large quantities, and the cost of single product is relatively high.

Mastars' industrial prototype service, with products and services that exceed customer expectations, is well-known in Europe and the United States, and has a high customer reputation. The industry covers a wide range of fields, including automobiles, motorcycles, health care, outdoor sports, home appliances, household goods, 3C Electronics, agriculture and stage lighting, etc.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China