Contents

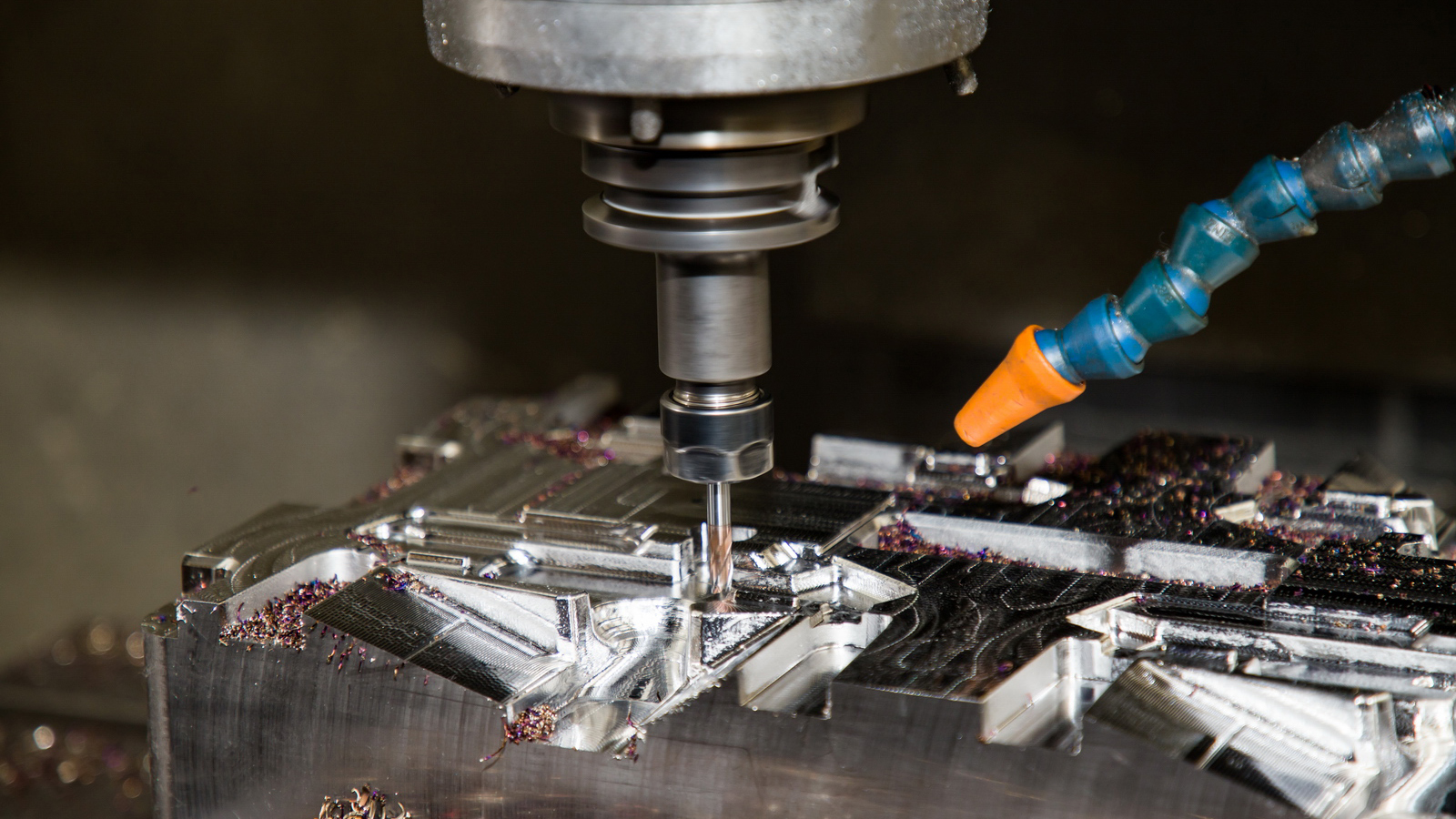

Mastars' rapid prototyping service can provide various prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

Titanium alloy and aluminum alloy are two different materials, which are widely used. Now let's have a look at the differences between titanium alloy and aluminum alloy.

What are the differences between titanium alloy and aluminum alloy?

1. Titanium alloy with different colors is a kind of silvery white metal and has better properties. Aluminum alloy is a non-ferrous metal with good strength and strong moldability.

2. The density of titanium alloy is 4.54 grams per cubic centimeter, which is lighter than steel and heavier than magnesium. It also has good high temperature resistance. The density of aluminum alloy will be smaller, only 1 / 3 of that of iron, and it has low melting point, high moldability and easy processing.

3. Different titanium alloys for different purposes can be used to make aircraft, which can carry more weight, and can also be used to make submarines, which are not easy to be corroded and dive deeper. Aluminum alloy is commonly used in aluminum alloy doors and windows, and has also been widely used in aerospace and machinery.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China