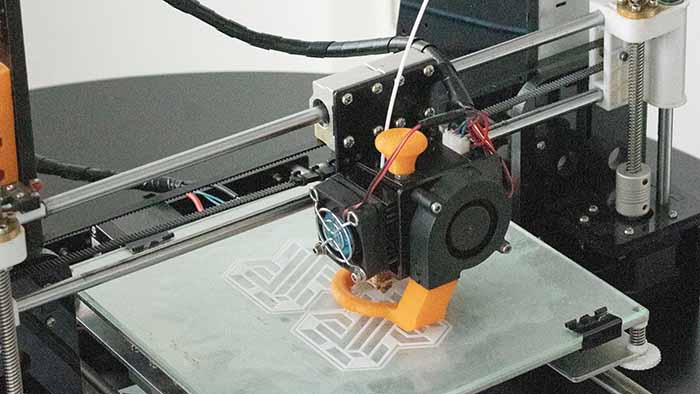

Mastars provides one-stop industrial manufacturing services. Many products in Mastars' rapid prototyping service are processed by CNC. In the automotive field, Mastars has deep cooperation with Bentley, Aston Martin and other world famous brands to produce prototyping and mass production of auto parts.

Cylinder blocks, cylinder heads, crankshafts, camshafts, connecting rods, etc. of automobiles are mostly processed by CNC machining with high efficiency, high performance and high reliability. At present, the diversified and personalized demands of automobile users for automobiles force automobile enterprises to update their products more quickly. The modular machine tool (special machine) production line that has dominated the automobile manufacturing industry for many years has been unable to meet the realistic requirement of the rapid update of the automobile industry. Today, CNC is the primary method for manufacturing many industrial-grade standard auto parts.

CNC machining has the following advantages:

1. High precision

2. Excellent product consistency

3. Multi-axis linkage

4. Highly automated

5. Low labor intensity

6. Short mechanical transmission chain – simple structure and high production efficiency

Auto parts

Now CNC machining is a method widely used in automobile manufacturing. Many parts are processed by CNC technology, which can ensure the precision, strength and consistency of products and efficient.

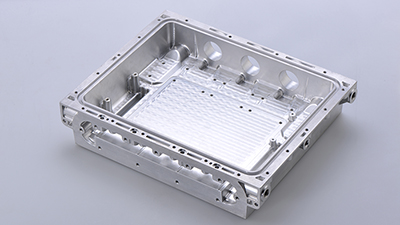

Gearbox

The gearbox is a vital transmission mechanism in automobile. The gearbox ensures that the engine power is transmitted correctly and efficiently to the wheels. Today, all the gears and shafts in the gearbox are precisely machined by CNC. A variety of different CNC techniques, such as milling, turning and surface grinding, ensure the reliability and precision of the shafts and gears in the gearbox to transmit power in the most efficient way.

Transmission shaft

The transmission shaft is also an important transmission mechanism that transmits power from the gearbox and engine to the wheels. The two main hypoid gears on the central shaft of the transmission shaft must be machined by CNC to provide the highest precision. The CNC also machines the bevel gears in the differential to provide a smooth ride and stability.

Headlights and Taillights

Since many top automakers have come up with complex headlight and taillight designs, CNC machining is the perfect match. Manufacturers are able to carve complex shapes out of solid blocks, creating clear, smooth, and complex-shaped headlights and taillights for excellent light transmission.

Engine

It’s an engineering marvel in the history of automobile manufacturing, providing powerful power in a small engine. About three years ago, 2-litre engines could provide up to 100 HP, while today's engines can provide a staggering 200 HP at the same specification. Why are the two different? The difference is due to the introduction of CNC machining, which has greatly improved the product tolerance and efficiency of the engine. CNC allows manufacturers to produce smaller engines but provide more power.

High-precision CNC machining has revolutionized the way of automobile manufacturing, greatly improving their performance. Mastars combines premium 5-axis CNC manufacturing technology with the latest CAM and CAD manufacturing software. Provide timely automotive product service solutions to ensure your automotive related products and prototypings can be manufactured quickly with the highest quality and precision.

Mastars Industries CO., LTD

www.mastars.com

• Email: marketing@mastars.com

• Tel: +86 755-88210689

• Fax: +86 755-8821 0685

• Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China(518104)