Mastars is a Chinese manufacturer. We can provide industrial product development and design, mold manufacturing, rapid cnc services, and rapid prototyping services

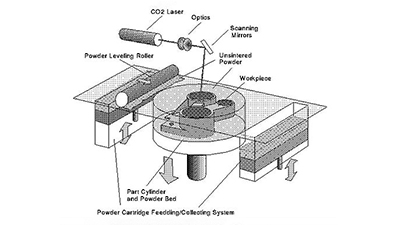

Recently, researchers at the University of Wisconsin-Madison have developed a new laser powder bed fusion (PBF-LB) process. According to the research team, the process can effectively reduce defect generation, such as porosity and cracks, during the production of metal additive manufacturing parts.

The process uses ceramic nanoparticles to control instabilities in the additive manufacturing process. The team explains that in the PBF-LB process, a laser melts a thin layer of metal powder, and then the material cools to form the finished metal part. However, when the laser interacts with the powder material, the powder surface heats to boiling temperatures and generates hot vapor.

This vaporization creates pressure that pushes down into the pool of melted material, causing droplets to spatter out. These droplets can cause unpredictable defects in additively manufactured parts, and the droplets can also merge to form larger droplets, creating more problems in the additive manufacturing process and resulting in substandard parts.

By coating metal powders with ceramic nanoparticles, the team was able to control the instability of the process. Using high-speed synchrotron X-ray imaging and theoretical analysis, they found that the nanoparticle coating stabilized the melt pool, preventing droplets from ejecting and forming larger spatters.

"With

metal 3D printing, we cannot consistently produce the same high quality and reliable parts as traditional methods, and we are concerned that using 3D printed parts for either critical or load-bearing applications is not a good choice," Lianyi Chen said, adding that "quality issues have always been the the biggest obstacle to widespread adoption of metal

3D printing."

"We demonstrate a potential way to address quality issues by making metal 3D printing technology more reliable, enabling it to produce consistent and defect-free parts," Chen continued, "Using our unique approach, it is possible to print metal parts that do not contain defects and quality comparable to off-the-shelf commercially manufactured parts."

In addition to the possibilities for additive manufacturing, Chen noted that this development could lead to improvements in a wide range of applications, including laser polishing, laser cladding, welding, casting, fluid stability control and more. "When nanoparticles were introduced, we found that they gave the droplets an almost 'armor' layer on the surface, so they don't fuse together when they collide," commented Minglei Qu, "and this is the got rid of the splash problem in metal 3D printing for the first time."