Some things you should know about mold product manufacturing

How Does Surface Finishes Affect Cost?

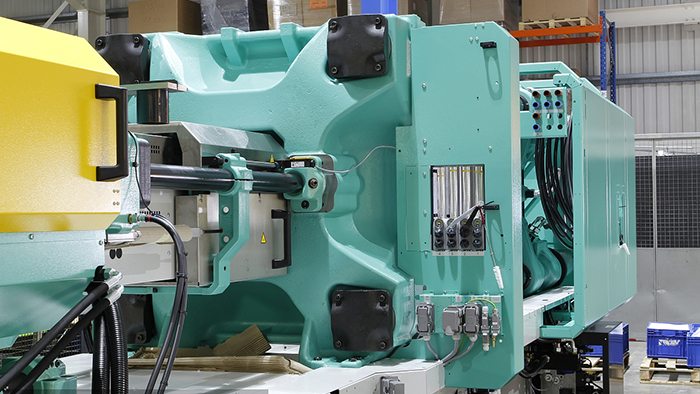

It is no surprise that various types of surface finishes are obtained using various types of processes. And the cost of obtaining the desired surface finish depends directly on the process, the machines and the materials used. So, in other words it is clear that finishing techniques that use more men, machines, or materials will cost more and others will cost less.Mastars can offer a complete service for components and sub-assemblies manufactured in engineering polymersSecondary operations include inserting, painting, printing, hot staking, ultra sonic welding, chrome plating and Vacuum metallization.

A typical example for the same can be Shiny finish. The materials used to obtain a shiny finish include things such as diamond powder. As such it is expensive to manufacture products with a shiny finish. Similarly, textures and surface finish obtained through the polishing process will be expensive as it does involve a good amount of human expertise and machinery. On the contrary, if you wish to go for textured finish, the products may not be that expensive. That is because textures can be obtained using s simple surface molding process using something as inexpensive as a sandpaper.

As such the surface finish and the processes used to obtain the finishing does affect the cost of the final product. Let us discuss the factors that you should consider while choosing mold surface structures.

Factors to Consider When Choosing Mold Surface Textures

When you are looking to manufacture high quality plastic products with the right kind of surface finish as per their usage, you must make sure you use the right mold to give the desired surface texture to your products. This may depend on a lot of factors and as such you must speak to your design expert or engineer to ensure you know what texture you need for the product you are manufacturing. Knowing what is actually required ensures you get the desired outcomes in terms of functionality as well as the design aesthetics.

To make it easier here are certain factors that will help you choose the right mold texture for your products.

Appearance and Function of the Product/Part

The mold texture should help you to improve the appearance of your products along with the functionality. It is therefore important to understand the level of aesthetic improvements you may need for the parts you are making. This will help you choose the grade you want while making sure the functional part of it is also taken care of.

Choice of Material

Different materials and chemicals used will have different effect on the surface texture. Properties such as the melting point of the material used can have a good impact on your product’s surface finish. Then there are certain additives that can improve the quality of your finish. This makes it important to that you choose the right materials that can be used to obtain the desired surface texture.

Injection Speed and Temperature

The injection speed of the material in its molten form also is a major factor in determining the surface finish quality. If you need a glossy finish, a fast injection speed would be needed. The temperature at which the mold is used is another factor to consider. Based on the surface texture you need these requirements cane be determined accordingly.

Conclusion

It is therefore important to keep in mind the various surface textures, finish types and standards that can be used as specifications of your parts. Use this piece as a guide to understand what works best for your requirement and how you can go about making the perfectly finished plastic parts.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China