FAQ and solutions for metal cutting processes

Mastars is a

metal prototype maker, Mastars uses CNC technology to make prototypings and functional parts, providing customers with

rapid prototyping services and high-precision parts production. Mastars has the world's leading

CNC machine tools and leads the industry in CNC processing industry.

The cutting of metal materials has many classification methods, common according to the process, material, forming these three classification methods. The main factors affecting the cutting quality are machine tools, cutting tools, fixtures, workpiece blanks, cutting fluids, technology and so on. How to improve the cutting accuracy and efficiency has attracted much attention, the following is a brief introduction to the common problems and solutions of the cutting process:

Influence factors of cutting process

1. Influence of process mechanics. The force of cutting process is the main factor affecting the accuracy, including equipment, tools, parts of the workpiece in a long time in the state of force, resulting in slight shape deformation, and eventually lead to the processing of parts are affected.

2. Influence of process heat. Generally speaking, there are three kinds of thermal deformation of tool, thermal deformation of parts, thermal deformation of machine tool itself and its components, which directly affect the results, including the generation of chip tumor, tool wear and so on.

Common problems in lathe cutting

1. Hardening. Tool in the cutting process, because the workpiece is affected by high temperature and high pressure, such as cutting tool, chip, so that the surface hardness of the workpiece has been improved, known as hardening.

2. The built-up edge. BUE are deposits on the tip of a knife. Under high temperature and high pressure, the part of chip in contact with the tool front surface forms a retention layer due to the influence of friction. Some materials in the stagnation layer will adhere to the tool tip front surface, forming BUE.

3. Vibration ripple. Tool, workpiece, machine tool components in the case of insufficient stiffness vibration, longitudinal or transverse ripple, will make the surface finish significantly reduced.

4. Galling. Galling refers to that when turning, the chip wraps around the surface of the workpiece, resulting in scratches, burrs and so on.

5. Bright spot. Due to the severe friction and extrusion caused by the wear of the back tool surface, the surface of the block or strip formed bright block.

Solutions for cutting processes

1. Numerical control programming skills. Numerical control programming is the basis of numerical control cutting technology, the pros and cons of programming directly affect the accuracy and efficiency of the machine tool, so it is necessary to choose a reasonable programming scheme according to the complexity of the workpiece.

2. Setting of cutting route. When NC milling the workpiece, it is necessary to select the appropriate feed mode in combination with the technological requirements of the workpiece, and try to cut in and cut out along the extension line of the contour curve, so as to avoid tool marks at the junction. At the same time, in milling, forward milling or reverse milling should be selected according to the workpiece conditions.

3. Setting of cutting route. In the workpiece CNC milling, the workpiece should be combined with the process requirements to choose the right way, as far as possible along the contour curve of the extension line cut, cut out, so as to avoid the intersection of knife marks. At the same time in the milling should be selected according to the workpiece conditions milling or milling.

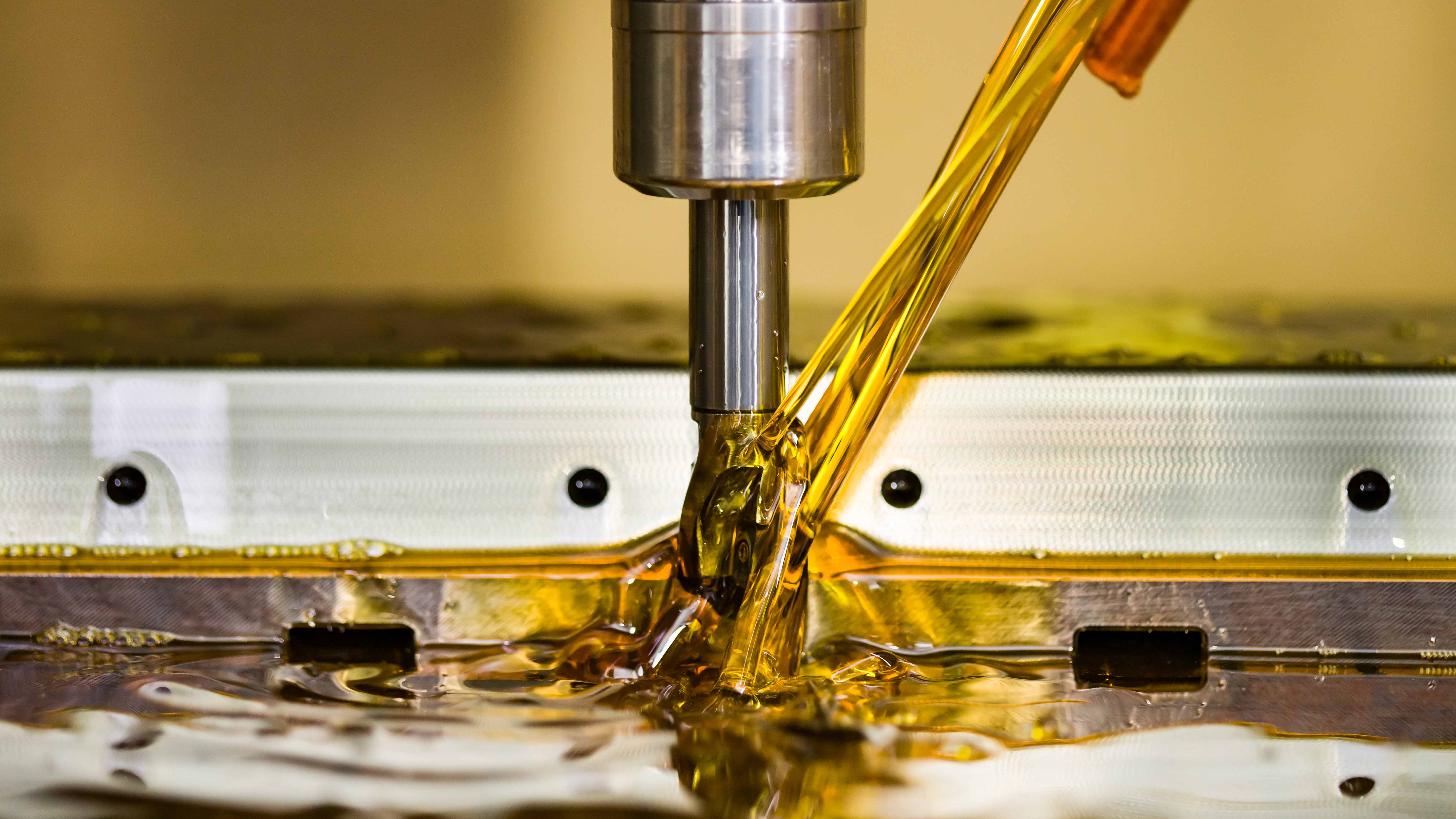

Selection method of cutting AIDS

Cutting AIDS are a kind of media that must be used in cutting process. They mainly play the roles of lubrication, cooling and cleaning in the cutting process. The selection of cutting AIDS directly affects the tool life and workpiece accuracy. In addition, the performance requirements of cutting AIDS must be considered in process arrangement and process efficiency.

The above is the common problem and solution of metal cutting process, in the actual cutting need to combine the workpiece, tool, equipment and other factors analysis, in order to get a reasonable process.

Mastars is an expert in CNC machining, with more than 20 years of industry experience, making rapid prototyping for major companies around the world, as well as mass production, if you have a demand for prototyping production, please contact us immediately, you will get the best quality products, and the best service.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China