Prototype is the first step to verify the feasibility of product design. It is the most direct and effective way to find out the defects and deficiencies of designed products, so as to improve the defects, avoid expensive mold manufacturing costs, reduce R&D risks and speed up R&D efficiency.

Mastars' rapid prototyping service can provide various prototyping services including 3D printing, CNC machining and vacuum casting, according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

So, what are the common methods of designing prototype processing?

1. 3D printing

Now 3D printing is often used to make single and small batch prototypes, which can be used to test the appearance, structure and performance of designs.

SLA(Stereo Lithography Appearance) rapid prototyping technology is suitable for making small and medium-sized workpieces, and can directly obtain products of resin or similar engineering plastics. SLA rapid prototyping has good surface quality, high system resolution and high molding accuracy. It is often used to make appearance and structure prototypes.

SLS is called powder sintering. Nylon material has high printing strength and toughness, but the surface has a sense of frosted powder. It is generally not used for the prototype of appearance parts, but often used for functional prototype. Metal materials can also be used for printing, making metal prototypes with frosted powder on the surface.

Advantages and disadvantages of 3D printing

Its advantages: fast - low cost - complex parts processing - the particularity of SLS materials;

Its disadvantages: material strength is not high and easy to break - not resistant to high temperature -precision is not high - can not be mass produced. The product is difficult to do post-processing.

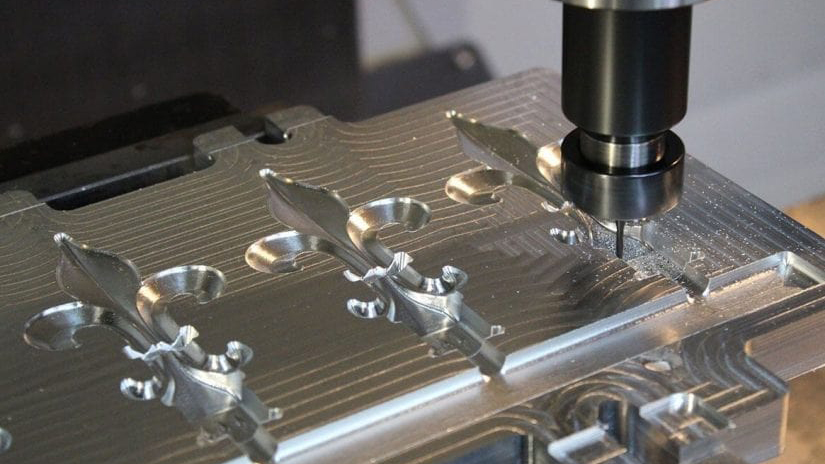

2. CNC machining

CNC is widely used in the mechanical processing industry, and the technology is relatively mature. For prototype processing, the effect and precision are also very good, but the cost is high. There are many materials suitable for CNC processing, including metal parts and plastic parts except silica gel and soft glue.

CNC machining technology is suitable for the whole process of prototyping.

Its advantages: high dimensional precision -high machining repeatability - excellent material properties;

Its disadvantages: high cost.

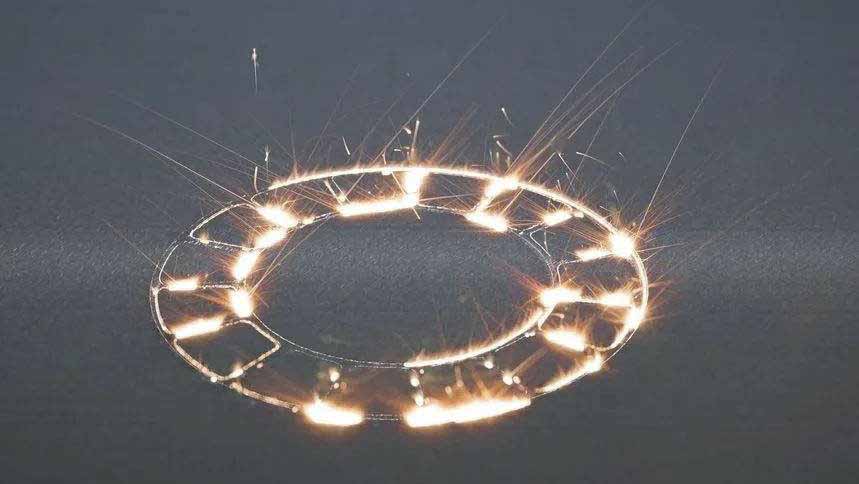

3. Vacuum casting

Vacuum casting refers to using the original template to make a silicone mold in a vacuum state, and pouring it with PU material in a vacuum state, so as to clone a replica that is the same as the original template. It is mainly used for the production of plastic prototypes, and can also be made of silicone or soft rubber prototypes. Its characteristics are that it does not need to open the mold, the molding speed is fast, and the production cost is low. One silicone mold can make about 20 plastic parts, which is suitable for small batch customization.

Mastars

Mastars' industrial prototype service, with products and services that exceed customer expectations, is well-known in Europe and the United States, and has a high customer reputation. The industry covers a wide range of fields, including automobiles, motorcycles, health care, outdoor sports, home appliances, household goods, 3C Electronics, agriculture and stage lighting, etc.

Mastars has a professional team of engineers and service teams, adhering to the spirit of craftsman in industry, to provide comprehensive solutions for your product development and production. At the same time, our company meets the customized order requirements of customers in various industries with the tenet of multi-variety, small batch and fast delivery.

So if you have any needs for prototype parts or mass production, please feel free to contact us, we are the most suitable partner that you have been looking for.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents:

Mastars rapid prototyping service, 3D printing, CNC machining and vacuum casting

1. 3D printing

Advantages and disadvantages of 3D printing

2. CNC machining

Advantages and disadvantages of CNC machining

3. Vacuum casting

Mastars