Mastars is a prototype company in China. With our own factory, we adopt mature prototyping technologies (rapid CNC machining, rapid sheet metal prototyping, vacuum casting prototyping, 3D printing prototyping etc.), take new concepts or designs and bring them to life.

Sheet metal is one of the most adaptable processing technologies in the manufacturing industry. Traditionally, steel, aluminum, brass, copper, tin, nickel, titanium or other precious metals are used to manufacture sheet metal. The thickness varies, but there are mainly two differences: thin plate and thick plate. Many different industries rely on the versatility and durability of sheet metal, including aerospace, home appliance manufacturing, consumer electronics, industrial furniture, machinery, transportation, etc.

1. how to use sheet metal?

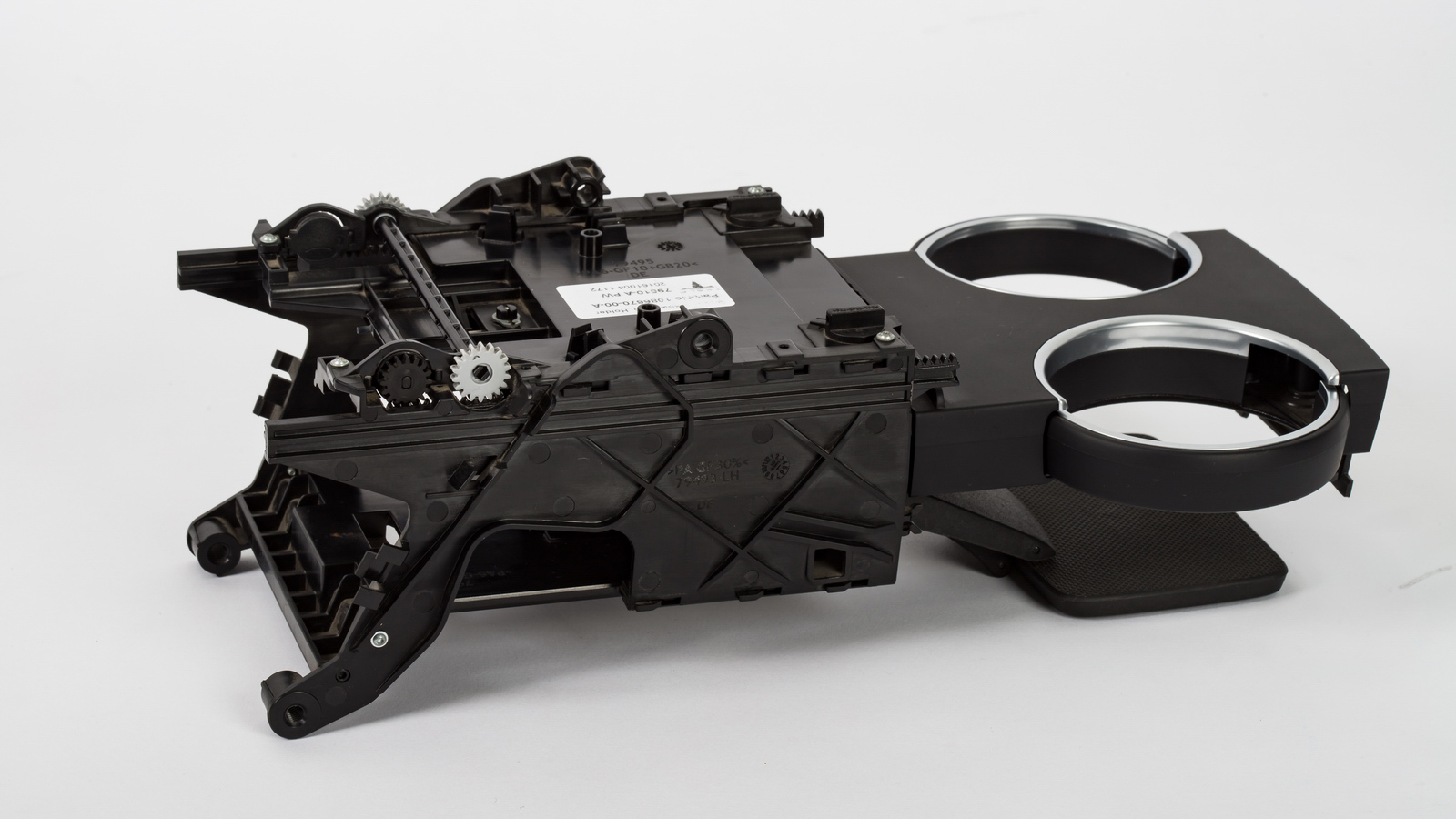

Sheet metal can be cut, stamped, formed, stamped, sheared, bent, welded, rolled, riveted, drilled, tapped and machined. Hardware can then be inserted to secure electronic components, metal brackets, or other sheet metal parts.

To finish the metal plate, it can be brushed, electroplated, anodized, powder coated, liquid spray painted, screen printed, laser etched and pad printed. Of course, parts can also be riveted into complex components.

2. sheet metal processing technology

Sheet metal is flat at first, but before that, it came from large ingots and then rolled into long strips of the required thickness. Then, these rolled coils are flattened and cut into different lengths according to large pieces to meet the needs of the manufacturing workshop. Examples of cold forming processes are as follows:

Cutting

Shearing is one of the longest methods of cutting plates, but has since been replaced by faster and more accurate methods.

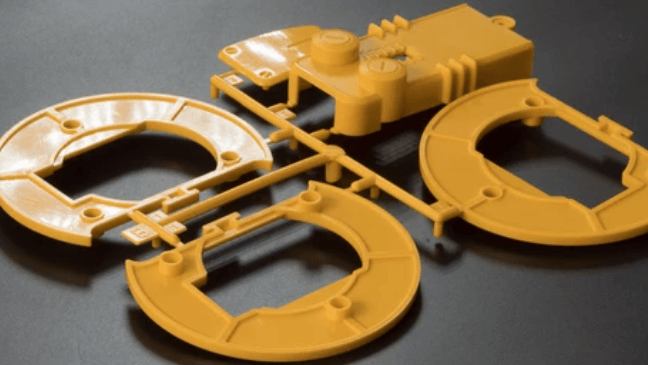

Stamping machines use tools called punches and dies, which can punch holes and shapes to produce any number of patterns. It is especially suitable for cutting simple patterns which are more economical than cutting on laser cutting machine or water jet. The punch can run hundreds of times per minute, which makes it a suitable Center for rapid machining parts.

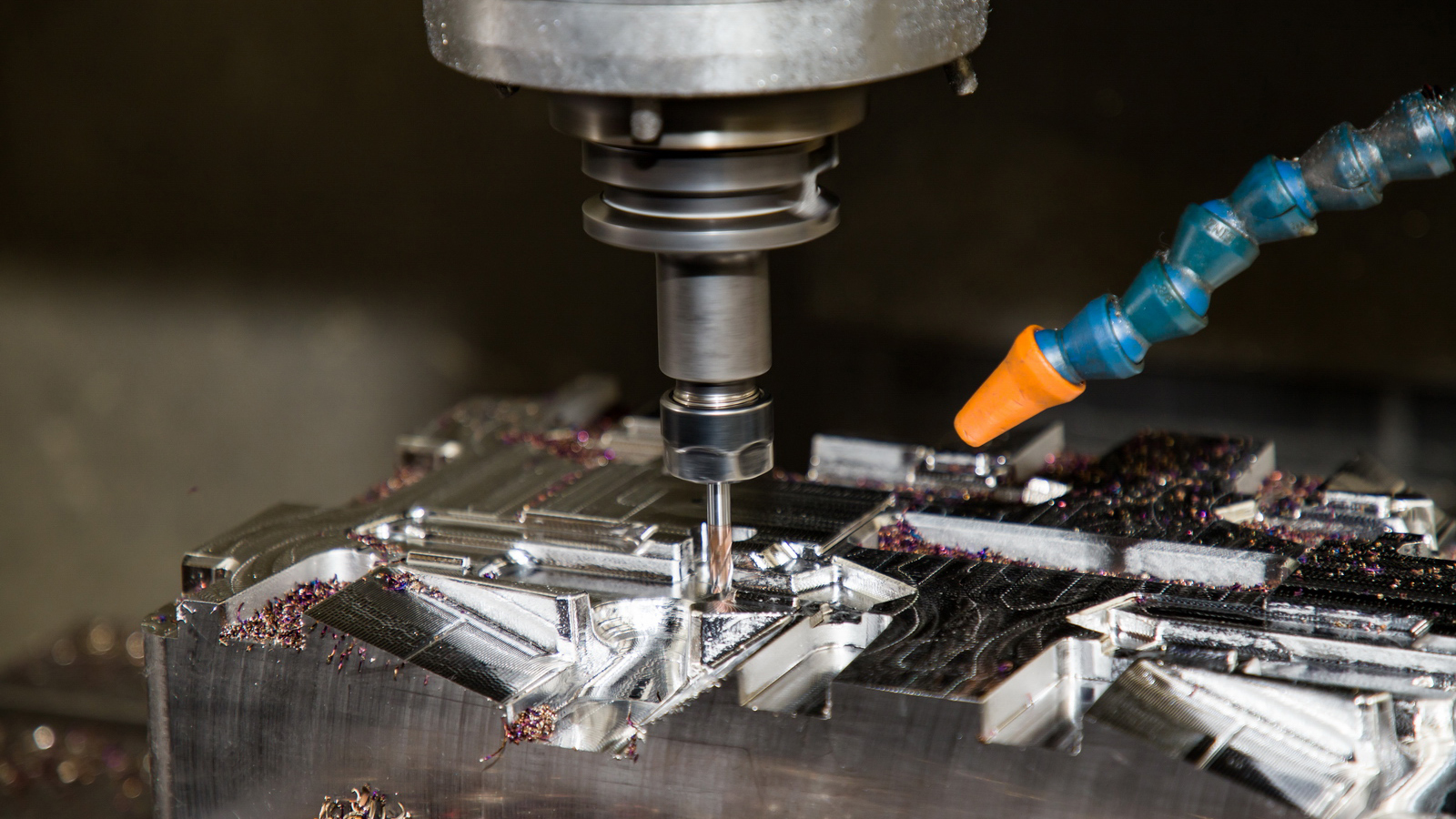

Laser cutting can be mixed with oxygen, nitrogen, helium or carbon dioxide to burn off the material and produce clean edges. This form of cutting allows very strict tolerances to be maintained.

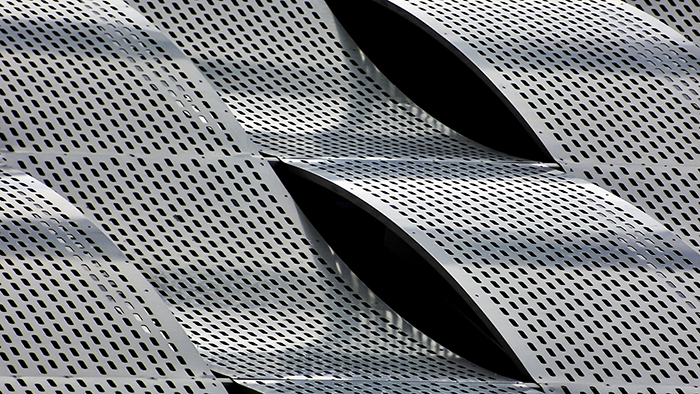

Photochemical processing is the process of using CAD generated templates to control etching to retain patterns that are chemically activated to remove unwanted materials.

3. sheet metal processing surface treatment

There are several ways to complete the surface treatment of metal plates:

Brushing is used to remove and remove surface defects of sheet metal parts. The resulting surface pattern is a uniform parallel grain, which is produced by the brush moving on the metal surface in one direction.

Electroplating is the process of coating metal layers on different types of metal objects. This process is usually carried out for aesthetic purposes or for more practical reasons, such as corrosion and wear resistance.

As a method of finishing, polishing metal plate is to grind off the oxide layer and the thin layer of the material itself. This makes the metal smooth, removes blemishes, and makes it glow again. Usually, start with coarse sandpaper, such as 40 to 80 coarse sand, and then work towards fine sandpaper to complete the polishing effect.

Powder coatings produce hard coatings that are harder than conventional coatings. Powder coatings can come in any color, so when durability and aesthetics are ideal finishes, it is a great way to customize the finish.

Abrasive blasting, commonly referred to as sand blasting or medium blasting, is the operation of forcibly pushing the abrasive flow to the surface under high pressure to smooth the rough surface, roughen the smooth surface, form the surface or remove surface pollutants.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

+86 18100294997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China