A Detailed Guide to Sheet Metal Fabrication

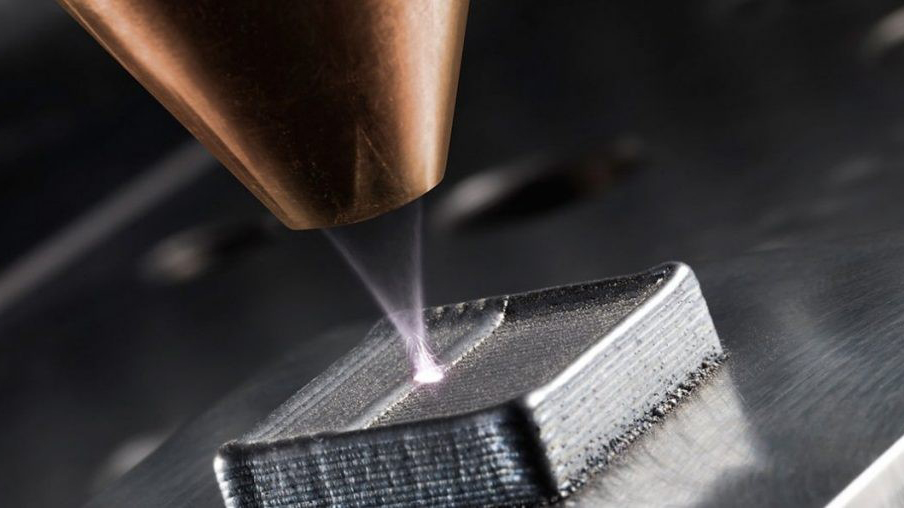

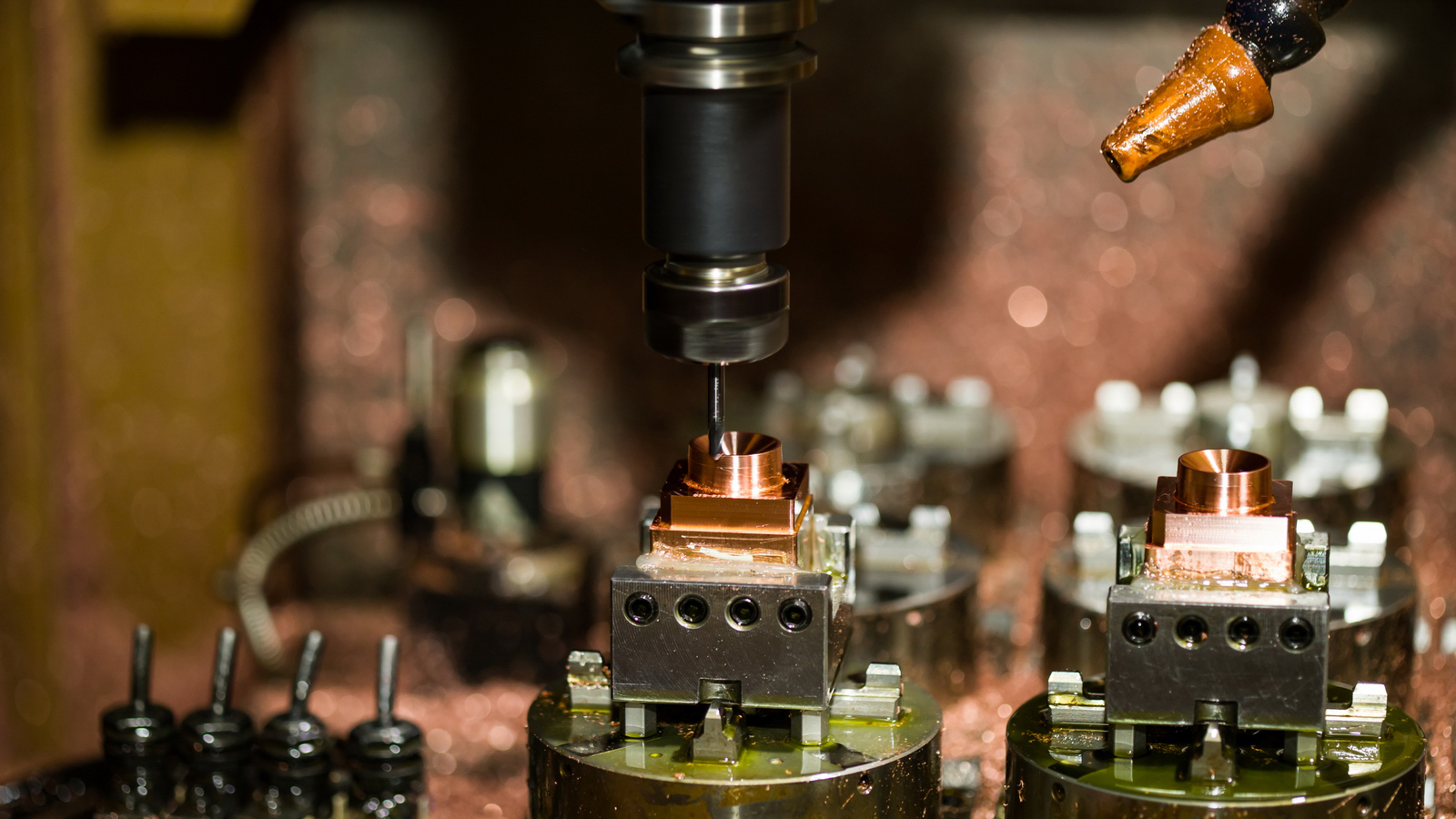

Metal sheet manufacturing is an excellent development and production process for creating durable functional elements like panels, hooks, and enclosures.The technological process of sheet metal processing refers to the whole processing process in which the shape, size, material properties or assembly and welding of parts change gradually in a certain order until sheet metal parts meeting the shape and size requirements are manufactured. For complex structural parts, their production and processing can generally be completed through multiple processes such as material preparation, setting out, blanking, forming and assembly. Moreover, due to cold working, sheet metal processing is often combined with welding, metal cutting, heat treatment and inspection

Sheet metal production, on the other hand, differs from other manufacturing procedures in that it entails several different operations, each of which manipulates the steel plates differently. Machining the metal, molding it, or putting multiple parts of it together are different operations.mastars provide rapid prototyping services and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining

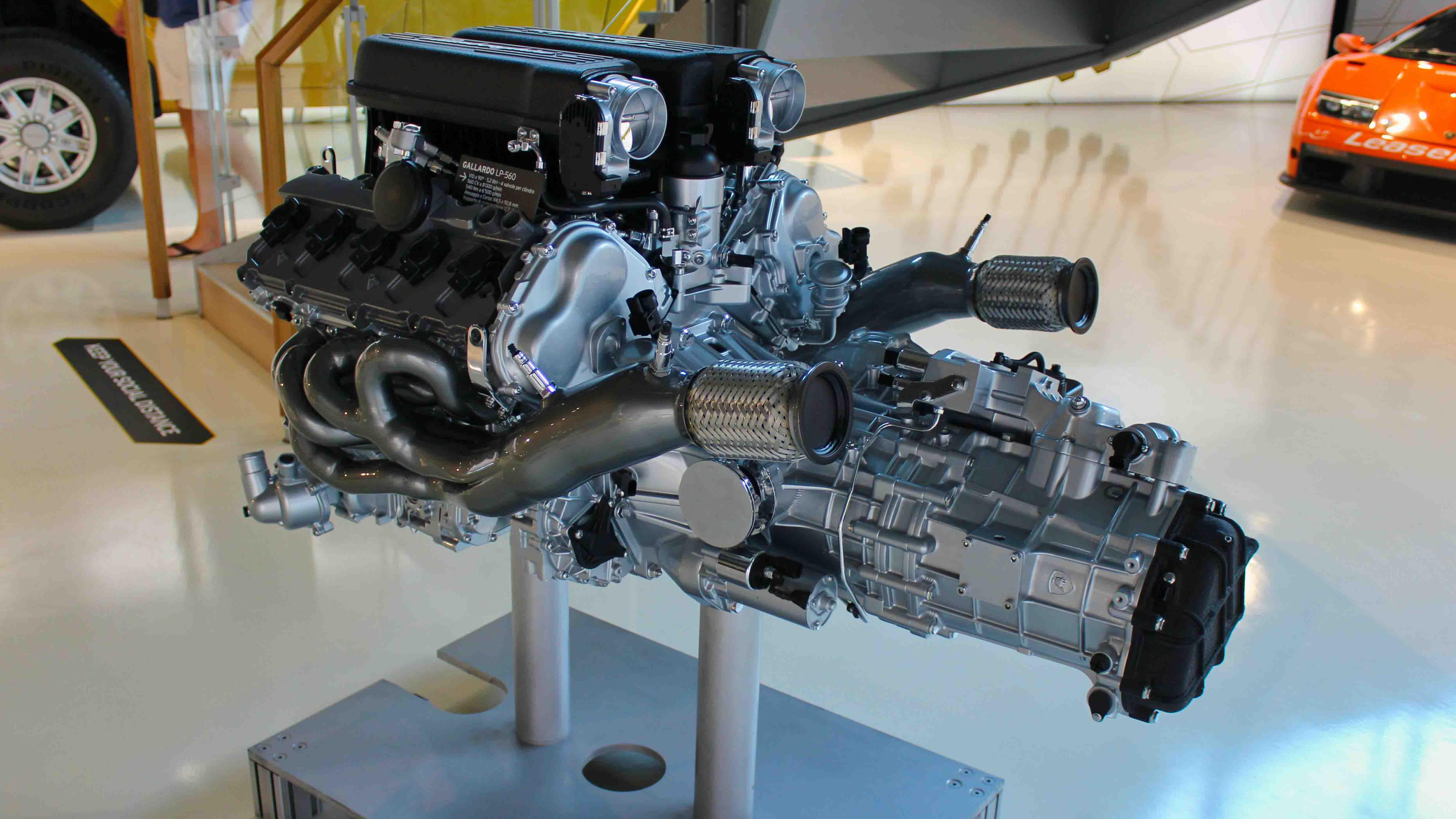

1. With the development of automobile, communication, it and daily hardware manufacturing, sheet metal processing has become more and more popular, and it is more necessary to understand sheet metal processing.

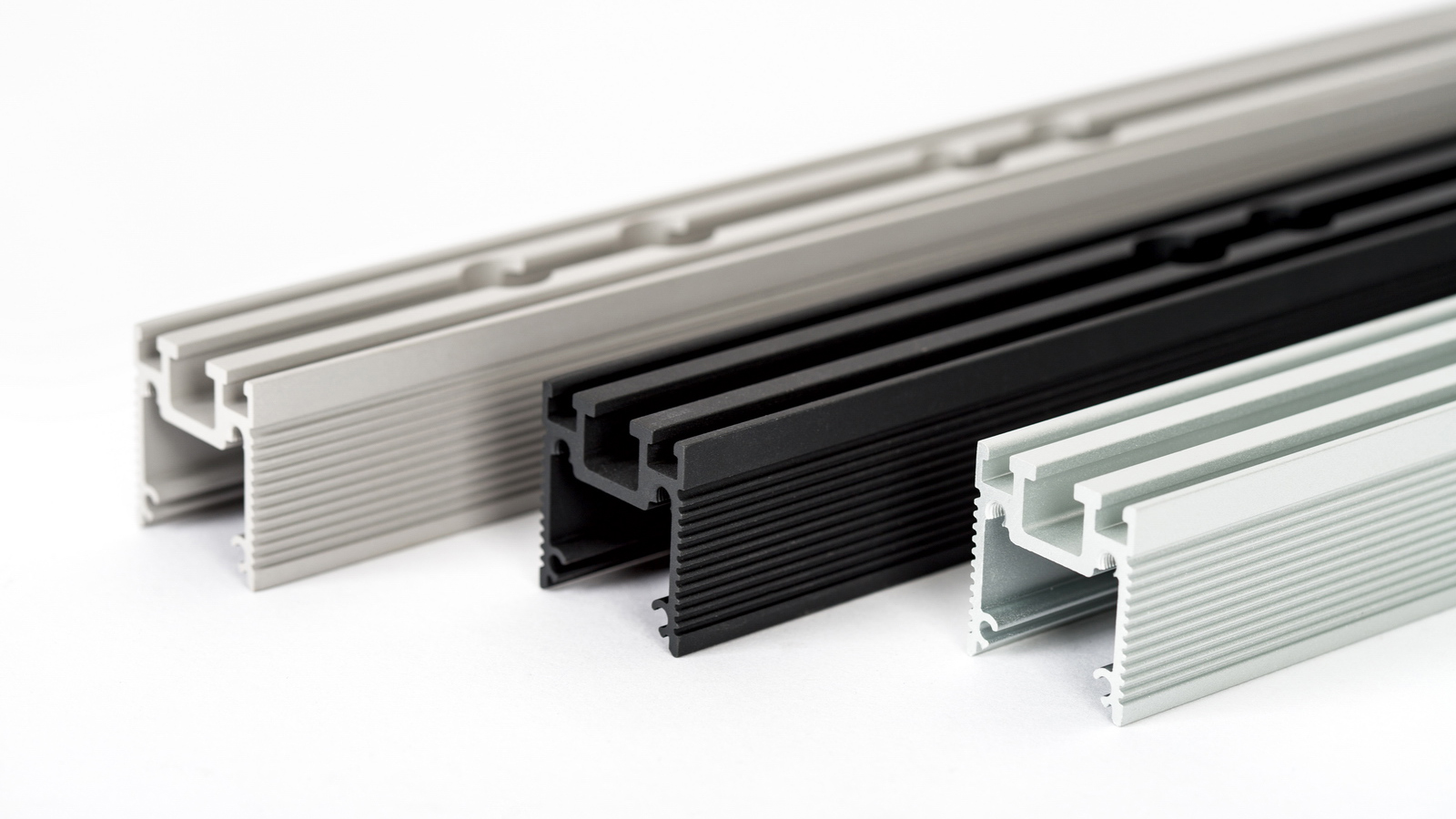

2. The operation of making metal sheet, profile and pipe into parts with certain shape, size and accuracy by manual or mechanical methods is called sheet metal processing; It is widely used in the manufacture of ventilation and air conditioning pipes and their components.

3. Most sheet metal parts are made of sheet metal and pipe fittings. Because of its light weight, high strength and stiffness, arbitrarily complex shape, less material consumption, no need for machining, smooth surface and other characteristics, it is widely used in daily life and industrial production, such as barrel, basin, ventilation pipe, material conveying pipe, automobile panel processing, etc. in addition, it can also be used in automobile external repairable work.

4. Sheet metal processing usually refers to the methods of shearing, bending, calendering, turning over and forming. Generally speaking, the process of completing various deformation processes with molds is called sheet metal stamping process, while the process of forming sheet metal manually or mechanically is called sheet metal plus.

Sheet metal material:

1. Electrolytic plate: SECC (n) (fingerprint resistant plate), SECC (P), dx1, DX2, SECD (tensile plate). Material hardness: hrb50 ° + - 5 °, tensile plate: hrb32 ° ~ 37 °

2. Cold rolled sheet: SPCC, SPCD (tensile sheet), 08F, 20, 25, Q235-A, CRS. Material hardness: hrb50 ° + - 5 °, tensile plate: hrb32 ° ~ 37 °.

3, aluminum plate; Al, Al (1035), Al (6063), Al (5052), etc.

4. Stainless steel plate: SUS, SUS301 (302303304), 2Cr13, 1Cr18Ni9Ti, etc.

5. Other commonly used materials include: pure copper plate (T1, T2), hot rolled plate, spring steel plate, aluminum zinc plate, aluminum profile, etc.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents

Mastars

automobile

Metal sheet manufacturing