Can be making the parts in Aluminum (6061/6063, T4/T5/T6 and other series ), stainless steel(304/316 and other series), copper, brass, carbon steel, ABS, PC, Nylon, PVC, Delrin and some like this kind of metal and plastic material.

Machining parts on a CNC machine tool mainly depends on the processing program. It is different from an ordinary machine tool. There is no need to manufacture and replace many tools and fixtures, and there is no need to frequently adjust the machine tool. Therefore, CNC machine tools are suitable for occasions where parts are frequently replaced. That is, it is suitable for a single piece, small batch production and the development of new products, shortens the production preparation cycle, and saves a lot of process equipment costs.

The machining accuracy of CNC machine tools can generally reach 0.005~0.1mm. CNC machine tools are controlled in the form of digital signals. Each time the CNC device outputs a pulse signal, the moving parts of the machine tool move by one pulse equivalent (usually 0.001mm), and the machine tool advances The average error of the backlash of the transmission chain and the lead screw pitch can be compensated by the numerical control device. Therefore, the positioning accuracy of the numerical control machine tool is relatively high.

When processing the same batch of parts, on the same machine tool, under the same processing conditions, using the same tool and processing procedure, the cutting path of the tool is exactly the same, the consistency of the parts is good, and the quality is stable.

CNC machine tools can effectively reduce the processing time and auxiliary time of the parts. The spindle speed and feed range of the CNC machine tools are large, allowing the machine tools to carry out powerful cutting with large amounts of cutting. The CNC machine tools are currently entering the era of high-speed machining. CNC machine tools move parts. The rapid movement and positioning and high-speed cutting of the semi-finished product reduce the process turnaround time of the semi-finished product and improve the production efficiency.

6) Improve working conditions

After the CNC extra bed is adjusted before processing, input the degree and start the machine tool to automatically and continuously process until the end of the processing. Operators are mainly engaged in input, editing, loading and unloading of parts, tool preparation, observation of machining status, and parts inspection. The labor intensity is greatly reduced, and the labor of machine tool operators tends to be intellectual work. In addition, the machine tool is generally closed processing, which is clean and safe.

The processing of CNC machine tools can accurately estimate the processing time in advance, the tools and fixtures used can be standardized, and the management is now spent. CNC machine tools use digital signals and standard coding as control information, which is easy to realize new standardization of processing. At present, it has been organically combined with computer-aided design and manufacturing, which is the basis of modern integrated manufacturing technology.

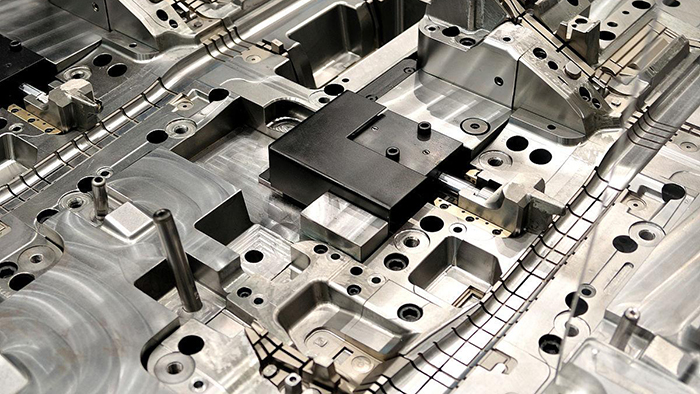

Rapid prototype machining makes the number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification. The processing quality is stable, the processing accuracy is high, and the repeat accuracy is high, which is suitable for the processing requirements of aircraft. In the case of multi-variety and small batch production, the production efficiency is higher, which can reduce the time of production preparation, machine tool adjustment and process inspection, and the cutting time is reduced due to the use of the best cutting amount. It can process complex profiles that are difficult to process by conventional methods, and even process some unobservable processing parts.

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents