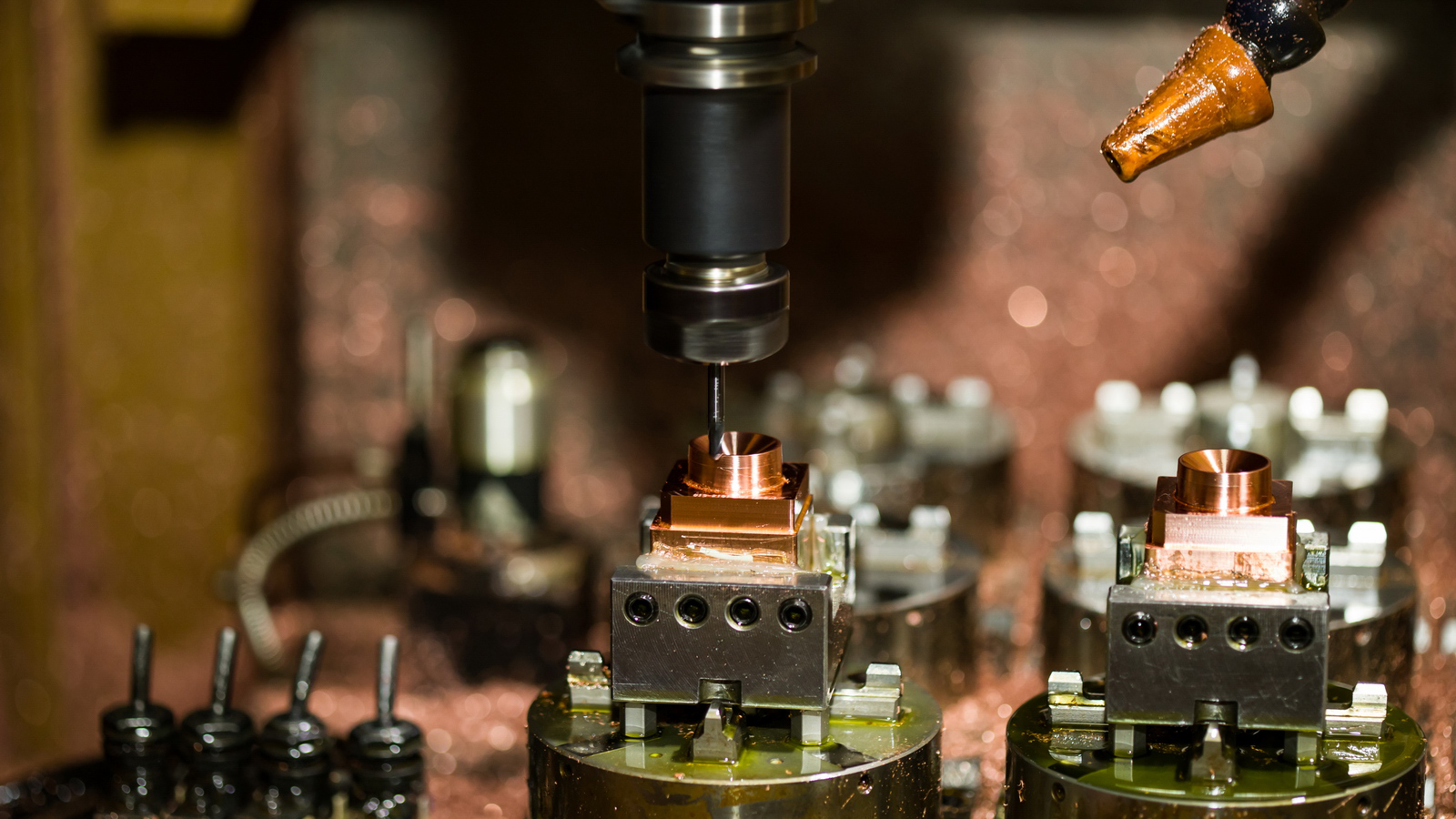

Mastars has a precision plastic mold and

injection molding team with rich theoretical and practical experience. The have a number of core technologies and patents in complex mold structure, mold flow analysis, conformal cooling technology, processing thermal deformation management.

Injection molding and blow molding are two processing technologies of mold products. They have their own characteristics. In short, blow molding adopts the mode of "injection + blowing", and injection molding adopts the mode of "injection + pressure". Injection molding is a solid core, blow molding is an empty core, the injection mold has a gate section, and the surface of blow molding mold and air blowing outlet are uneven.

1. Injection mold

Injection molding is the injection molding treatment of materials, that is, melt the plastic materials, then inject them into the mold cavity, cool the plastic after entering the mold, and then process it into the required shape. The shape formed is the final appearance of the finished product, so there is no need for other processing. In addition, the injection molding process can well control the details. In the injection molding process, protrusions, ribs, threads and other parts can be formed in one step.

2. Blow mold

Blow molding is a rapidly developing plastic processing method, also known as hollow blow molding. The processing principle is: put the thermoplastic resin or tubular plastic blank obtained by injection molding into the mold, and then inject compressed air into the mold after the mold is closed to inflate the plastic blank and close to the inner wall of the mold, and then obtain the required hollow products through cooling and demoulding.

It is worth mentioning that, very similar to blow molding of hollow products, the manufacturing process of blow molding film does not use molds in principle, which is completely different from processing injection molding. According to the billet production method, blow molding can be divided into extrusion blow molding and injection blow molding. The new development direction is multi-layer blow molding and stretch blow molding.

3. Difference between blow molding and injection molding

In fact, the product expression form of injection mold and blow molding mold is the main difference. The products manufactured by injection molding process are usually thick, relatively simple to manufacture and relatively low requirements for raw materials. Blow molding processes are different, and the products are thin and transparent. Because of this, there are certain requirements for the toughness and tensile properties of raw materials, and the processing requirements of blow molding molds are relatively high.

Injection mold and blow mold are widely used in daily life, and they have their own advantages and characteristics, and their development prospects are good.

Mastars provides one-stop industrial manufacturing services. In the automotive field, Mastars has deep cooperation with Bentley, Aston Martin and other world famous brands to produce prototyping and mass production of auto parts.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China