Art lighting product -- light up the world

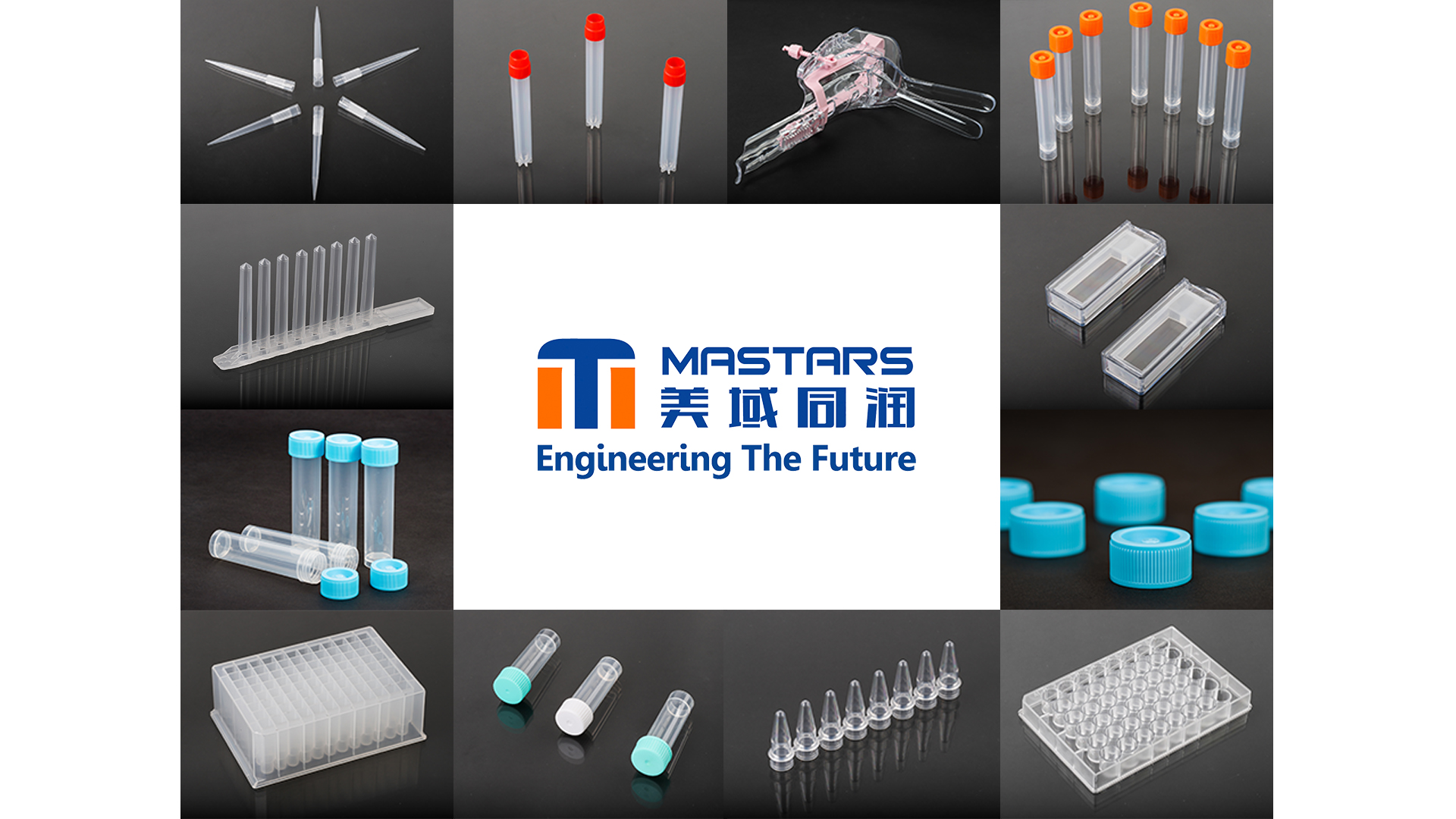

In the field of art lighting, Mastars has carried out in-depth cooperation with the world's top enterprises for many years, providing one-stop services from product prototyping to mass production, covering the application of a variety of production processes such as prototyping, mold design, mold production, injection processing, die casting and so on.

About product

This Q series product is a set of high-end stage art lamps newly launched on the market. It consists of dozens of components, subdivided into each component, and each one adopts different materials and production processes.

Clients and Projects

Client H has been our important partner for many years. Company H is a global company that designs and manufactures artistic lighting. It owns a world-renowned brand. In its business field, Company H has a leading position in the industry.

We have cooperated with H company since 2010. In the past 12 years, we have produced various series of lamps and lanterns, which have been applied in various fields around the world. Mastars' technology and efforts light up the world.

Product List

Since there are many components of the product, here we have selected some main components to introduce.

YOKE COVERMaterial:PC+ABS FR3010

Tooling Type:Injection molding

YOKE COVERMaterial:PC+ABS FR3010

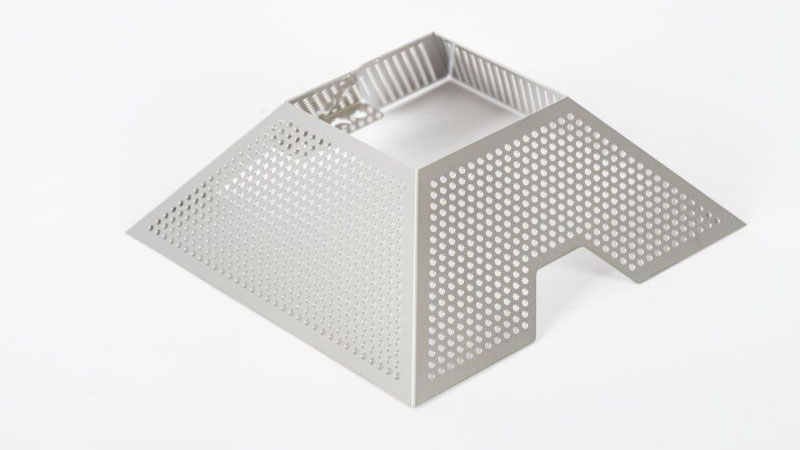

Tooling Type:Injection molding YOKE CHASSISMaterial:Aluminum ADC12

YOKE CHASSISMaterial:Aluminum ADC12 TILT WIRE FIXATION BRKTMaterial:POM 9044

TILT WIRE FIXATION BRKTMaterial:POM 9044 YOKE BLOWER BRACKETMaterial:PC+ABS FR3010

YOKE BLOWER BRACKETMaterial:PC+ABS FR3010 YOKE AIRE GUIDE BOTTOMMaterial:PC+ABS FR3010

YOKE AIRE GUIDE BOTTOMMaterial:PC+ABS FR3010 UI FRONTMaterial:PC+ABS FR3010

UI FRONTMaterial:PC+ABS FR3010 PSU BOX HOUSINGMaterial:Aluminum ADC12

PSU BOX HOUSINGMaterial:Aluminum ADC12 PAN SHAFTMaterial:Aluminum ADC12

PAN SHAFTMaterial:Aluminum ADC12 CNC milling serviceMaterial:Aluminum ADC12

CNC milling serviceMaterial:Aluminum ADC12 BASE LID BOTTOMMaterial:PC+ABS FR3010

BASE LID BOTTOMMaterial:PC+ABS FR3010 BASE LID TOPMaterial:PC+ABS FR3010

BASE LID TOPMaterial:PC+ABS FR3010 DISPLAY FRAMEMaterial:PC 2405 clear

DISPLAY FRAMEMaterial:PC 2405 clear FAN AIR GUIDEMaterial:PC+ABS FR3010

FAN AIR GUIDEMaterial:PC+ABS FR3010 HEAD FRONT COVERMaterial:PC+ABS FR3010

HEAD FRONT COVERMaterial:PC+ABS FR3010 STRAY LIGHT ABSORBERMaterial:PC LEXAN 945

STRAY LIGHT ABSORBERMaterial:PC LEXAN 945 FILAMENT BACKDROPMaterial:PC LEXAN 945

FILAMENT BACKDROPMaterial:PC LEXAN 945 ZOOM MOTOR HOUSINGMaterial:PC LEXAN 945

ZOOM MOTOR HOUSINGMaterial:PC LEXAN 945 CNC milling serviceMaterial:PC+ABS FR3010

CNC milling serviceMaterial:PC+ABS FR3010

Prototyping making

Each component has undergone prototyping verification, and the product design has been improved according to the problems that occurred in the prototyping design and production. Therefore, in the actual mass production, the problems encountered are relatively few and relatively small.

Mastars has rich experience and strong ability in prototyping and manufacturing and can find design problems and remind customers to improve, helping customers to smoothly transition to mass production.

Problem and solution

Due to our one-stop industrial manufacturing service, validation starts from prototyping, greatly reducing issues in mass production. But inevitably, there are still some small problems.

First example, the following problems have occurred in the component Wire Guide Yoke:

1) Some critical dimensions are out of specification, must optimize it.

2) Burr on inner hole will damage wires, must adjust and improve it.

3) Injection gate material is out of surface, should meet 2D drawing requirement.

4) There is extra symbol at cavity 2, will make confusion.

5) There is flow mark at injection gate area of some samples.

The solution is that we modify the mold according to the problems to correct these problems.

The second example, the handle, which is the key component with the greatest technological change, has more than 20 components that originally needed to be produced separately and reassembled. After changing our thinking and design, now we can cast it at one time, which greatly saves the time and cost of customers, and improves the precision and intensity of the product. We have a very detailed description before, you can browse: https://www.mastars.com/Article/handle.html , maybe it will inspire your industrial design and processing.

Other small problems that are easy to occur, such as dimensional tolerances, fit tolerances and surface finish, can be easily solved by modifying the mold and process.

Based on Mastars' years of experience in similar product design and production, as well as its own strong development and production capabilities, we can always easily deal with product problems and solve them at the fastest speed to ensure the delivery cycle.

The effect

During the delivery cycle, components of different materials and different processes all meet the requirements and expectations of customers and meet the delivery standards. 200 sets of finished products will be delivered in advance, and production will continue in the future.

One-stop solution

The company has an experienced design and production team, German HERMLE 5-axis CNC machining center, AGIE Electrical Discharge Machine, Sodick Electrical Discharge Machine, Okuma, FANUC and other precision mold processing equipment, Sumitomo, Sodick injection molding machine, as well as CMM fully automatic Measurement laboratory.

We maintain long-term and good cooperative relations with world-renowned enterprises in various industries, and we are fully capable of providing one-stop industrial manufacturing services for global enterprises.

1.Receive product needs of customers, conduct efficient professional communication, fully understand and deepen customer needs.

2. Verify your original design by making the prototyping of the product, and help you find some defects in the design during the prototyping production process, so as to make more adequate preparations for the feasibility of mass production in the future.

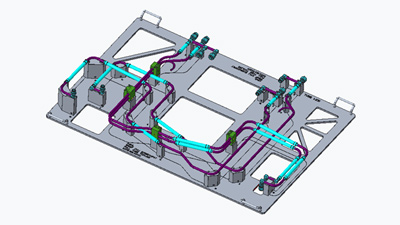

3. After the acceptance of the prototyping, design the mass production products, conduct 3D modeling, design the mold, and determine the feasibility of the design scheme through mold flow analysis.

4. Make use of rich industry experience and advanced automation equipment to manufacture all kinds of high-precision molds.

5. Large-scale production and processing, comprehensive processing technology: CNC precision machining, 3D printing, injection molding, metal injection molding (MIM), die casting, metal stamping, etc. Meet all your machining requirements.

6. Comprehensive product post-surface treatment process: polishing, oil spraying, powder spraying, sandblasting, anodizing, electroplating, etc., to create more perfect surface effect and better surface performance for your products.

7. Our testing center has advanced comprehensive testing equipment, such as German GOM ATOS TRIPLE Sacn III Blue ray 3D scanner, Swedish Hexagon CMM, 2.5-dimensional automatic image measuring instrument, Hitachi handheld X-ray fluorescence spectrometer, Switzerland TESA Height meter, Japan Mitohiro Roughness Meter, etc. All this ensure that your products meet the design and functional requirements.

8. Perfect after-sales service, professional engineering technology and sales staff 7x24h to respond to your after-sales needs.

Customer voice

Anderson, account manager in charge of global new product development, said: "As far as I know, we have been working with Mastars for 12 years, much longer than I've worked in company H. Mastars has grown into a world-renowned company now, and our business is growing. Why have we been able to cooperate in various product series for 12 years? I think that speaks for itself. There is no doubt that Mastars is a global industrial manufacturing service provider. They are very excellent, from design to manufacture, not only brought us the best products, which are sold all over the world, but also helped us improve a lot of design and save us a lot of cost. I believe our cooperation will continue for a long time to come, and will be very tacit and pleasant, which is very important."