cost—The soft rib of large-scale application of additive manufacturing

|3D printing /rapid prototyping service CNC machining/custom metal stamping

Compared with the traditional material removal machining technology, additive manufacturing technology is a new manufacturing technology based on digital model, which accumulates materials layer by layer to produce physical objects, reflecting the close combination of network information technology, advanced material technology and digital manufacturing technology. The emergence of additive manufacturing technology has brought a new solution to the key problems of complex structure optimization design, rapid design verification, rapid manufacturing of small batch parts, rapid customer response and so on, because it has the advantages of realizing die free, fast, full dense and near net shape of high-performance complex structural parts.

In the practical application of additive manufacturing technology, cost has become a key factor restricting the large-scale promotion of this technology. 38% of practitioners believe that although additive manufacturing technology has unique advantages, its high cost is the biggest weakness of additive manufacturing. Generally, additive manufacturing is only suitable for small batch trial production of complex structural parts.

In order to realize the commercial application of any new technology, we must make a clear analysis of the cost composition of the technology, including additive manufacturing. For additive manufacturing products, the following seven aspects should be considered in calculating the cost:

Design and development cost: the cost of product structure design, function simulation and process verification. Generally speaking, the product structure of additive manufacturing is more complex than the traditional structure, the performance requirements are higher, and the cost of design and development is often higher.

Raw material cost: consumption of parts, supporting materials and other materials. You can add another 30% - 40% on the basis of the final weight of the product as a rough judgment of the raw material cost.

Post treatment cost: including heat treatment, wire cutting, machining, hot isostatic pressing, manual grinding, polishing such as abrasive flow, surface carburization and nitriding. For some complex products or products with high precision requirements, the post-processing cost even exceeds the printing cost.

Labor cost: the labor cost involved in production, including human resource expenses incurred in model data preparation, machine preparation, printing process monitoring, machine cleaning and maintenance, post-processing, production management, etc.

Indirect costs: including design simulation and other software costs, utilities and gas costs, rent and other indirect costs.

Risk cost: the loss of printing failure. Generally, the longer the printing time, the higher the risk of failure; The larger and more complex the model structure, the higher the risk of printing failure. It is not uncommon for some products to fail to print 1-2 times.

At the part design stage, the printing placement direction and location are considered. It shall be designed as a self-supporting structure as far as possible to reduce the number of supporting structures required; Maximize the number of parts placed on the construction platform and print more parts at a time; Reduce the height of parts as much as possible and reduce the printing time.

The post-processing method is considered in the part design stage. Minimize the dead space, reduce the workload of powder cleaning and the difficulty of support removal; Try to design the surface with poor print quality as the surface that needs to be machined later, so as to reduce the workload of surface grinding and polishing; Reserve positioning, clamping and other positions to facilitate subsequent processing.

The printing layer thickness is considered at the part design stage. Maximize the printing layer thickness and minimize the impact of printing step effect on the product. For areas with obvious step effect, they are either designed as areas to be machined later or areas that are insensitive to surface finish.

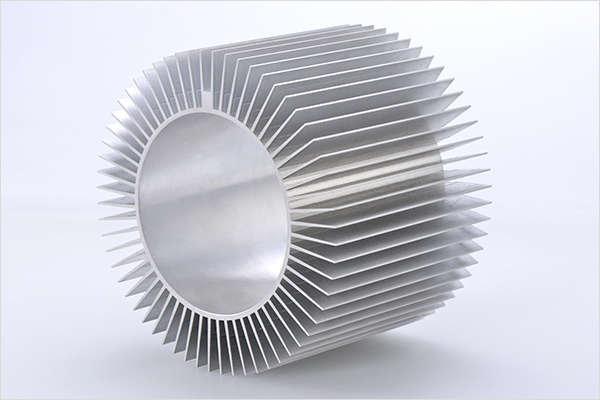

Lightweight structure. Lightweight structural design can not only reduce the material cost and printing time, but also increase the bearing efficiency of the structure and reduce the operation cost of the system

Structure / function integration. Taking advantage of the digitalized and intelligent manufacturing of additive manufacturing, the shape coordination of macro meso micro scale is fully considered in the structural design, and other functional indicators are met on the basis of the bearing function of the structure itself.

Change the production / business model. As a kind of production equipment that relies less on digital manufacturing technology, additive manufacturing will likely change the production mode and business mode of some products, and bring huge economic and social benefits to enterprises and consumers..