Mastars is a prototype company in China. With our own factory, we adopt mature prototyping technologies (rapid CNC machining, rapid sheet metal prototyping, vacuum casting prototyping, 3D printing prototyping etc.), take new concepts or designs and bring them to life.

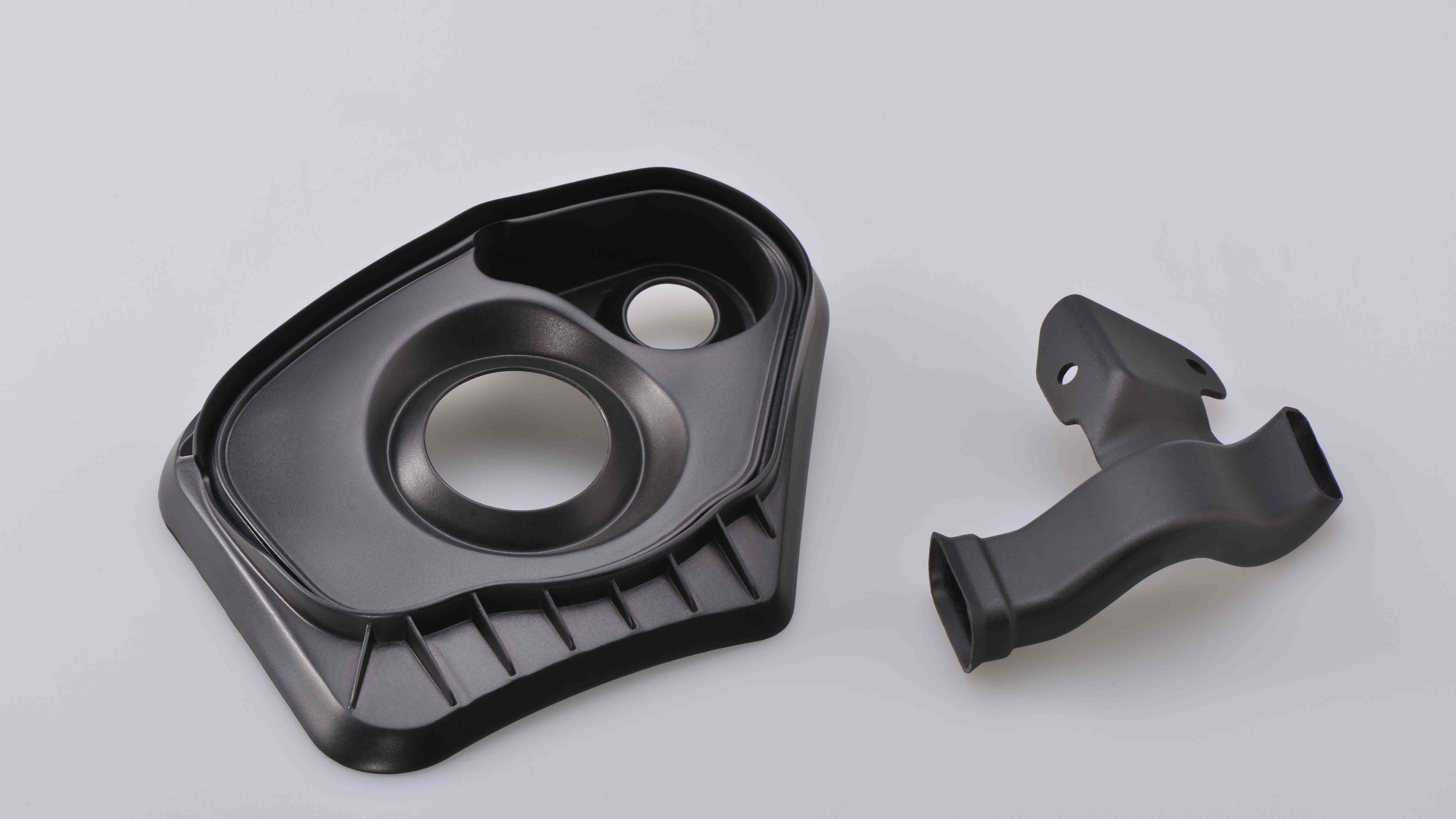

Insert molding refers to the molding method in which the pre prepared inserts of different materials are inserted into the mold, the resin is injected, and the molten material is bonded and solidified with the insert to make an integrated product. Injection molding on the substrate refers to the process of inserting injection molded parts on the local surface of the metal plate.

.

What is Insert Molding?

Insert Molding is the process of injecting plastic into a mold cavity and insert piece before plastic injection molding in order to yield a single piece with the insert engulfed by the plastic. It’s a process used to bolster the shape and functionality of plastic injection molded components. In other words, it refers to integrating other components, mainly metal parts into the injection-molded product directly.

The characteristics of insert molding are as follows:

1. The mutual combination of the formability and bending of resin and the rigidity, strength and heat resistance of metal can firmly make complex and exquisite metal plastic integrated products.

2. In particular, the combination of resin insulation and metal conductivity is used to make the molded products meet the basic functions of electrical products.

3. The pre molding combination of multiple inserts makes the post engineering of product unit combination more reasonable.

4. Insert products are not limited to metal, but also cloth, paper, wire, plastic, glass, wood, wire coil, electrical parts and so on.

5. For the rigid molded products and the bending elastic molded products on the rubber sealing base plate, after the integrated products are made by injection molding on the substrate, the complex operation of arranging the sealing rings can be omitted, making the automatic combination of post processes easier.

6. Because it is the joint between molten material and metal insert, compared with the press in molding method, the gap of metal insert can be designed narrower, and the molding reliability of composite products is higher.

7. Select appropriate resin and molding conditions, that is, for products that are easy to be damaged (such as glass, coils, electrical parts, etc.), they can also be sealed and fixed through resin.

8. By choosing the appropriate mold structure, the inserts can also be completely sealed into the resin.

9. With the combination of vertical injection molding machine, manipulator and insert whole column device, most insert molding projects can realize automatic production.

10. After the insert is formed, it can also be made into products with hollow grooves after core removal.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents